3D measurement plays a vital role in the automotive industry. It enables precise dimensional control of components and helps monitor deformations under load. It also accelerates the development of new parts by providing detailed data on vehicles and individual components. This brings you higher quality, fewer errors, and cost savings.

Methods of 3D measurement: contact and non-contact

3D measurement can be divided into several methods depending on the type of application and required accuracy.

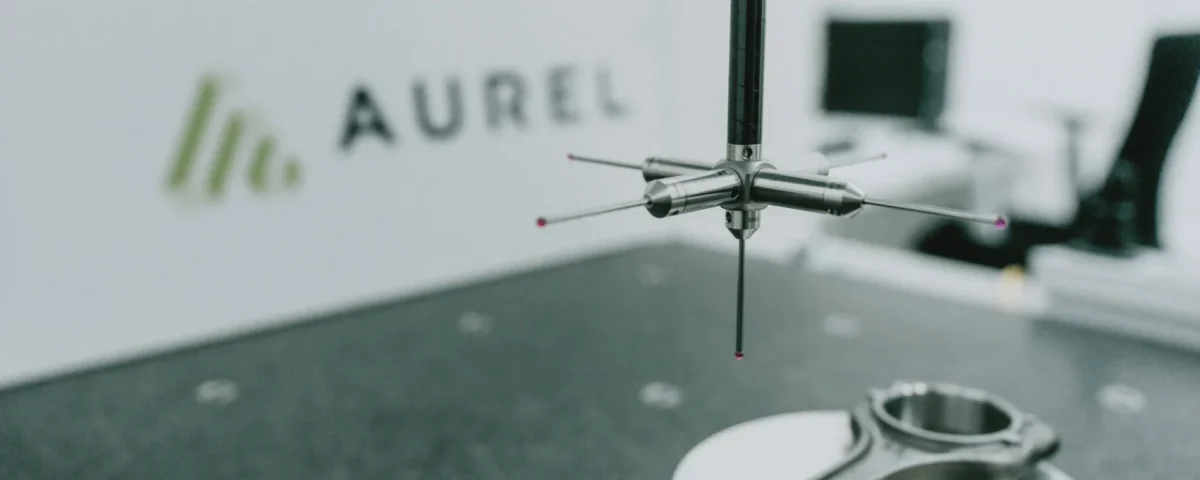

- Contact – Used for detailed dimensional inspection of parts where precise point sensing is necessary.

- Non-contact – Includes point-based static and dynamic analysis, as well as surface scanning.

We will measure anything – in production and in quality control

3D measurement allows you to precisely capture dimensions, shapes, and deformations of individual components, subassemblies, or entire vehicles. It’s used in all phases of development and manufacturing. From design and testing to final quality control. It helps you detect errors early, before they lead to costly consequences.

At AUREL, we measure parts of all complexities – from simple shapes to intricate geometries. Our technicians have measured everything from the size of a pin to a train car to an entire elementary school. We’ll provide you with high-quality 3D data for virtually anything. You’ll receive complete, clearly interpretable results. This will help you to optimise not only development costs, but also quality control and drawing documentation.

Modern technology, equipment, and a professional team

At AUREL, we are equipped with cutting-edge equipment, a large-scale experimental lab, and a team of experienced specialists. They will help you choose the most suitable measurement method for your needs. We combine various measurement techniques and use advanced equipment from Zeiss, Klingelnberg, Faro, IDT, Nikon, Canon, and others.

We offer companies:

- Precise point-based contact measurements

- Accurate point and surface non-contact measurements

- 3D dynamic analysis of high-speed processes

- Visualisation and virtual reality outputs

- A variety of photogrammetry and scanning methods

How does it work in practice? We frequently use 3D measurement in automotive testing, which is AUREL’s core area of expertise. For example, in accident analysis, we investigate the causes and assess the vehicle’s impact on the crash. Using 3D scanning, we capture the entire scene, including intersections, roads, and highways. The collected data can then be used for simulations in various software tools, which we integrate with our passive safety laboratories.

We present the measurement results in a clear and engaging way – through videos or even virtual reality. We also create detailed 3D models that can be used for visualization or 3D printing.

The benefits of 3D measurement? Accuracy, efficiency, and cost savings.

Implementing 3D measurement brings a range of benefits, including:

- Accuracy and Efficiency – Precise measurements help you quickly identify deviations, minimize errors, and optimize production. Even in the early stages of development.

- Improved Quality – Manufacturing defects are easily detected, ensuring that your products meet all required standards and specifications.

- Faster Development – 3D data speeds up the design and validation of prototypes. Fewer physical models mean faster time to market.

- Cost Savings – Early error detection reduces scrap, rework, and warranty claims. More efficient production saves both materials and time.

At AUREL, 3D measurement is more than just a technical service. It’s a powerful tool that supports faster product development, ensures quality, and reduces costs related to rework and customer complaints. We deliver comprehensive, high-quality results tailored to your specifications. In the format that best suits your project.

Contact us – we will tailor our 3D measurement service to your specific needs.