Metal surface treatment plays a crucial role in the automotive industry – it affects not only durability and functionality of individual parts, but also their service life, safety, and the quality of subsequent processing. AUREL offers comprehensive services in this field – from design through to the delivery of finished parts to the end customer. The company has in-depth understanding of the specific requirements of leading OEM and Tier 1 customers and has been successfully applying them in practice for over 20 years.

More than just a clean surface. AUREL manages the entire process

In the field of metal surface treatment, AUREL provides complete solutions for OEMs and their suppliers. From precise degreasing and multi-stage rinsing to passivation and phosphating. The result is a perfectly clean surface, fully prepared for further processing and compliant with strict OEM standards. AUREL relivers more than just a surface treatment – we also provide all related services, from component assembly and packaging to storage and final delivery.

Every surface process starts with perfect degreasing

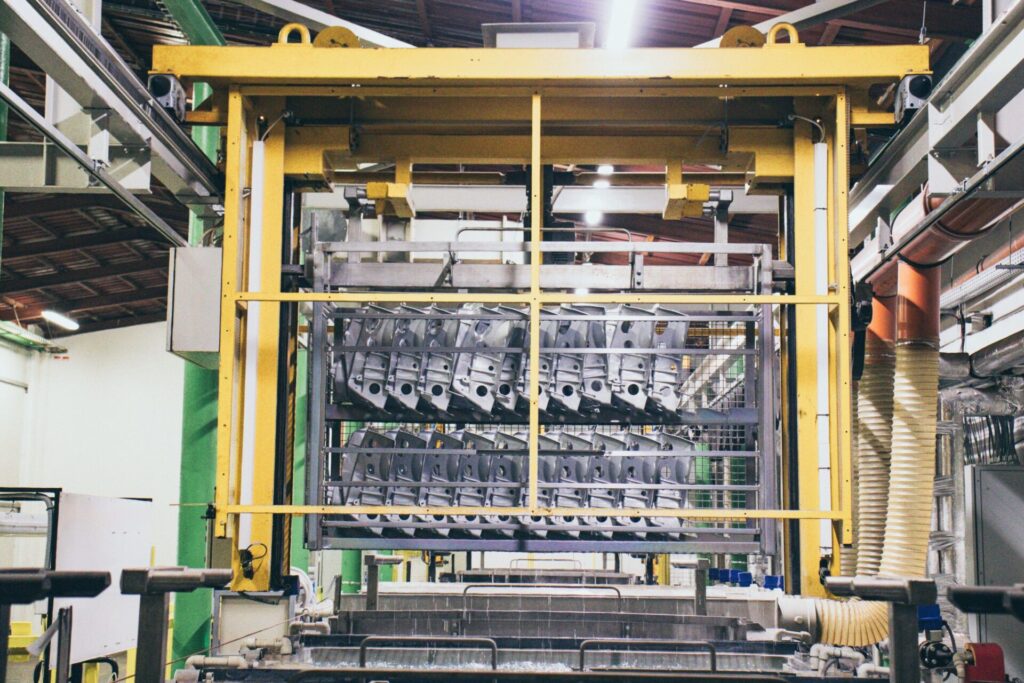

Thorough cleaning of metal parts is a crucial prerequisite for all subsequent treatments. The first step is degreasing, which ensures adhesion of subsequent layers, corrosion resistance, and overall product functionality. At AUREL, this process is carried out on three automated lines: two immersion lines that combine degreasing with passivation and phosphating, and one high-capacity continuous line dedicated specifically to ferrous parts.

Passivation and phosphating for greater durability, longer service life, and corrosion protection

Passivation extends the service life of components and significantly increases their corrosion resistance. Only a clean, homogenous, and well-wettable surface is properly prepared for further processing such as painting, welding, or bonding – and that is exactly what passivation ensures. At AUREL, we use chemical passivation on two fully automated immersion lines, which allows for the combination of various technologies. The lines are fully interchangeable – which means we can deliver parts on time, even when introducing new technology or chemistry.

Another cornerstone of surface treatment is phosphating – a chemical modification of metal surfaces, most commonly steel, aluminium, or zinc. This process creates a thin crystalline layer of insoluble phosphates firmly bonded to the substrate. Thanks to its porous structure, it significantly improves the adhesion of oils, paints, and other coatings, while at the same time providing high resistance to wear and corrosion.

We value a personal approach – and it’s more than just words on a website

At AUREL, we genuinely prioritise a personal approach. Our customers often come to us with specific or even unconventional requirements – and we are always ready to accommodate them. Whether it’s adjusting a technological process, validating new specifications, or implementing non-standard quality monitoring, we deliver. Thanks to our flexibility and, the backing of a strong holding we can design solutions that are both technically reliable and economically efficient. This is why customers return to us again and again.

Top-quality and reliability beyond automotive

Comprehensive services, a human approach, more than 20 years of experience, and a team of specialists – this is the combination that makes AUREL a strong partner across the entire automotive sector. Evidence of this can be seen in our long-lasting cooperation with a leading Czech car manufacturer and other major global OEMs.

But AUREL also excels in other sectors, such as engineering and rail vehicles, energy, aerospace, and forensic sciences. This was futher demonstrated during recent presentations of our technologies at three prestigious international events. These confirmed that our solutions are sought after not only within the automotive industry, but also across other fields – proving that our expertise and technologies are highly transferable to a wide range of industries.

Looking for a reliable partnet for metal surface treatment? At AUREL, you get end-to-end services from start to finish, combines with a personal approach that finds a solution for every challenge.