Metal degreasing may seem like a minor step, but in fact, it is a crucial operation that has a decisive impact on the final surface quality in the automotive industry. Every component must first undergo thorough degreasing to ensure adhesion of the protective passivation layer. Only then can subsequent processing take place. AUREL offers extensive and comprehensive surface treatment services to leading global car manufacturers. An essential part of these processes is degreasing.

Quality starts with cleanliness

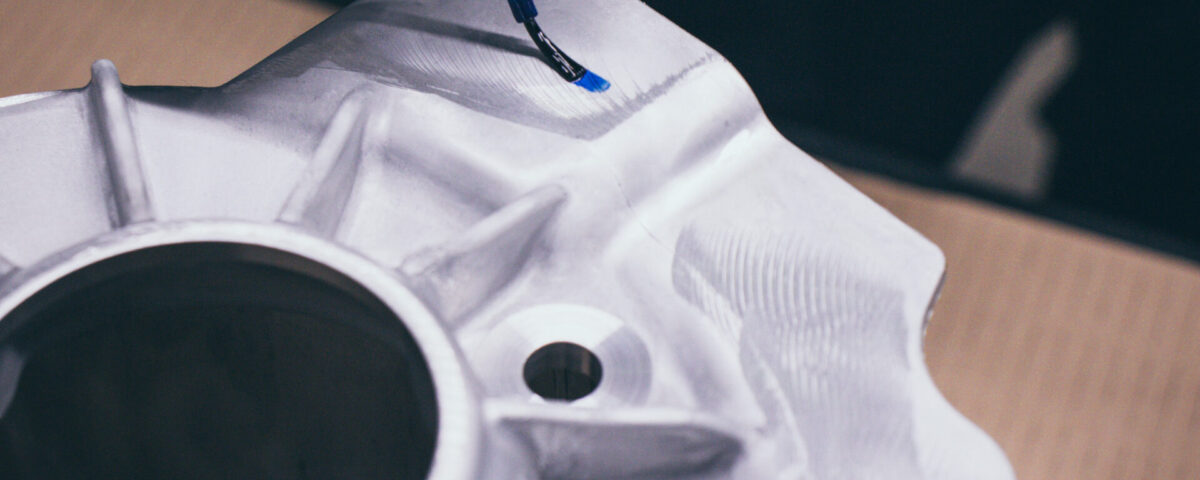

Metal parts often arrive from production contaminated with various impurities. Typically, it’s oils, greases, cooling emulsions, but also dust, corrosion, or oxidation residues. Their removal is vital not only for the adhesion of paints or phosphate layers, but also for the stability of subsequent processes such as bonding, assembly, or testing.

In the automotive industry, degreasing of metal parts is therefore a key step. Insufficient surface treatment will inevitably show up in the vehicle sooner or later. That is why surface cleanliness control and monitoring of degreasing process stability are integral to quality management systems and compliance with OEM standards.

Metal degreasing methods

The most common approach is chemical degreasing, usually with alkaline solutions, which realiably remove manufacturing contaminants from chassis, brake, or engine components. For complex or delicate parts, ultrasonic systems are often used, while plasma technologies are applied, for example, in the preparation of plastic components with metal inserts. Modern production lines rely on automation and online quality control, which are both essential to meeting strict OEM requirements.

AUREL – comprehensive services with a personal approach

AUREL provides a complete range of services in the field of metal surface treatment. Degreasing is an integral part of this process and is carried out on three automated lines:

- Two immersion lines – allowing degreasing to be combined with additional treatments (e.g. phosphating, passivation) according to customer requirements. If necessary, the technology can be adapted to new specifications.

- Continuous degreasing and passivation line – designed primarily for iron-based parts. Although the share of aluminium in the automotive industry is growing, many components are still made from iron alloys- This high-capacity line can process parts up to 1,000 x 350 mm in size and weighing up to 100 kg-

In addition to high-quality degreasing of aluminium structural parts and passivation, AUREL also offers a range of specialised services. These include, for example, the application of Collophon 507TM anti-vibration material, or assembly of components after surface treatment. We also provide packaging, warehousing, and logistics, delivering finished parts directly to the end customer.

Quality, flexibility, reliability

Degreasing is not just a preparatory phase before the next steps – it is a control point on which the quality of the entire production process depends. That is why at AUREL we emphasise technological precision and reliability, including compliance with environmental standards. Thanks to a high degree of automation, multi-stage processes, and direct deliveries, we have long provided solutions that meet the demanding requirements of both OEM and Tier 1 customers.

Do you need a reliable partner for mental surface treatment? At AUREL, we will provide you with a tailor-made solution – from thorough degreasing to the delivery of finished parts directly to you.