The AUREL plant in Chrastava is built on a combination of modern surface treatment technologies, precise quality control and a strongly customer-oriented approach. Operations Manager Michal Palounek explains how the team responds to demanding customer requirements and why trust is a cornerstone of successful cooperation. He also reveals how the idea for the new powder coating line was born – a step that opens the door for AUREL to industries beyond automotive.

How would you introduce the Chrastava plant to someone who doesn’t know you yet – for example an automotive partner looking for a reliable supplier?

We have been an established provider of surface treatment services for more than 20 years. We offer degreasing and passivation of aluminium structural parts and profiles, as well as steel stampings and weldments. We also operate a zinc phosphating line. In addition, we are able to provide almost any follow-up operation required by our customers. Comprehensive logistics services, including delivery to the end customer, are a given.

What exactly is your role in managing the plant, and what do you consider important when working with people?

I am responsible for all processes within AUREL’s production operations. I always try to build a team that is not only high performing but also works well on a human level. It is important that people do not come to work feeling stressed or discouraged. I communicate openly with my colleagues, explain critical feedback and praise good work. My door is always open, and I welcome critical opinions and suggestions.

What sets the Chrastava plant apart from other surface treatment providers?

I believe our main advantage is our strong customer-focused approach. You would search for the word “we can’t” in our vocabulary for a very long time. We always look for a way to meet the customer’s needs so they don’t have to look elsewhere.

What are the key technologies or processes you currently use in surface treatment?

We operate two immersion lines and one spray line for degreasing followed by titanium or silicon passivation. We also run an immersion zinc phosphating line and application equipment for applying anti-vibration compounds.

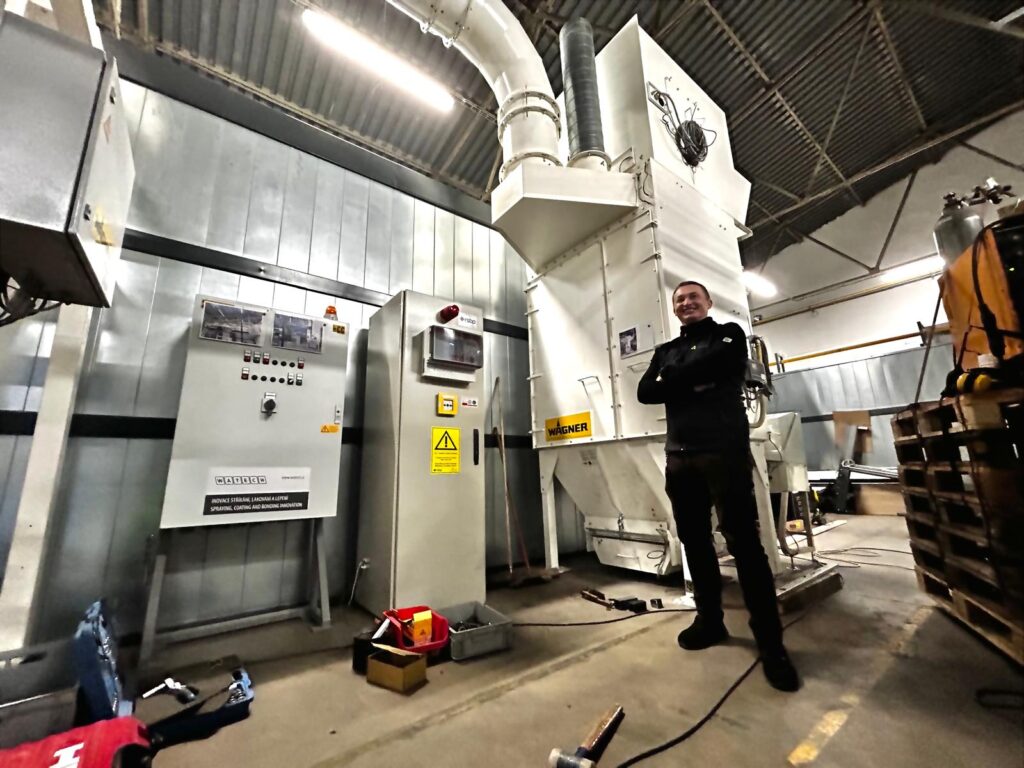

You are currently installing a new powder coating line in Chrastava. What new opportunities will this bring to your customers?

The main benefit is an expansion of our service portfolio. Parts that we passivate are always followed by some form of final surface finish – and powder coating is one such option. Operating our own powder coating line allows us to offer this service to our existing customers, and more importantly, to approach new customers, including those outside the automotive sector.

Automotive manufacturers and their suppliers are known for their high requirements. What demands do you most often encounter, and how do you respond to them?

In our case, the main requirements relate to the cleanliness of treated parts and the amount of applied passivation. To give you an idea, we must be able to measure coating thicknesses in the range of 2–15 mg per square metre – which is extremely low. We have a very well-equipped laboratory where we can perform these measurements and many others.

Do customers sometimes come with unusual requirements or urgent orders? How do you handle such situations?

I wouldn’t say urgent requests are an everyday occurrence, but they are certainly very frequent. We always do everything possible to accommodate our customers and meet their requirements. We are able to completely reorganise production or introduce an extra shift if needed. The result is above-standard relationships with our customers, which often lead to further business opportunities.

Can you give an example of a project where you had to adapt the process or technology specifically to customer needs?

We closely monitor customer demand. When a new opportunity arises that makes sense, we respond – for example, by building a painting line. That’s exactly how the powder coating line came about: a customer requested coating on passivated parts, and we identified it as an opportunity.

The market is changing due to new materials and vehicle design trends. Which technologies or types of parts do you think will be most important for your plant in the coming years?

I wish I had a crystal ball. In recent years, electromobility has been a dominant topic worldwide. At the moment, it feels like the automotive industry is standing still, waiting to see whether legislation will change and internal combustion engines will come back into play. A lot will depend on that decision. What is certain, however, is continued pressure to reduce vehicle weight, which suggests an increasing share of aluminium components.

What does your customer base look like across Europe? Are you looking beyond automotive?

Most of our customers are automotive suppliers from the Czech Republic, Germany and Poland. Our field is quite specialised and is used predominantly in automotive due to the high quality requirements. With the launch of the powder coating line, however, new opportunities outside automotive are opening up – and this is a direction we would like to pursue.

What should companies focus on when selecting a surface treatment partner? What matters most in the supplier–customer relationship from your perspective?

Trust is the most important factor. Customers must always be confident that we will do everything possible to meet their requirements, and at the highest possible quality. When a problem arises, they call AUREL, and there is a team ready to do its utmost to resolve it.

And what should they focus on? On the website aurelcz.eu. There they will find our contacts, and we will take care of everything else.