Surface treatments play a crucial role in the reliability and long-term functionality of components. High-quality surface protection ensures corrosion resistance, stability during subsequent processing, and the overall durability and functionality of parts. For this reason, manufacturers define precise standards that suppliers must meet in order for their products to pass quality tests and perform reliably under demanding operating conditions. AUREL consistently meets the specific and stringent requirements of leading global automotive manufacturers.

OEM standards – the foundation of trust and cooperation

AUREL holds all certifications that are considered an unwritten prerequisite for entry into the automotive supply chain:

- IATF 16949 – requirements for quality and process management systems in the automotive industry,

- ISO 9001 – quality management system,

- ISO 14001 – environmental management system,

- TISAX – information security,

- ISO 45001 – focused on occupational health and safety, currently in preparation.

In addition to these core standards, AUREL holds a number of additional certifications and meets even the most stringent brand-specific requirements. These include manufacturers such as Volkswagen, Mercedes-Benz, BMW, Audi, Porsche, Jaguar Land Rover, and many others.

One of the company’s key strengths is its comprehensive range of services, stability, and high reliability of both processes and deliveries. “Within the scoring systems of some of our major customers, we achieve the highest possible ratings – 100 points out of 100. This confirms that we are a trouble-free supplier with well-defined processes, high-quality surface treatments, and a minimal number of claims,” says Jan Sommer, Quality Manager at AUREL.

Detailed and strict requirements for surface protection

Each automotive manufacturer has its own specific and precisely defined requirements for surface treatments. Compliance with these requirements has a significant impact on overall component quality, particularly in terms of:

- Service life and functionality: The protective layer represents a key barrier against corrosion and has a decisive influence on component durability. If the surface is not properly protected, corrosion can significantly shorten the service life of parts and jeopardise their use within the vehicle.

- Suitability for subsequent processing: After surface treatment, the part must be suitable for further operations such as welding, bonding, or painting. These processes require a perfectly clean surface, free from grease residues or unwanted chemical substances.

- Resistance under real operating conditions: The applied coating must withstand not only laboratory tests but also real-world operating conditions – including temperature fluctuations, humidity, exposure to salt, and mechanical stress. Components must perform reliably even during long-term use.

- Aesthetic appearance and uniformity: Surface treatment is important not only for protection but also for design. A uniform standard ensures that all components fit seamlessly into the overall vehicle appearance, without deviations in colour or surface structure.

Quality testing and the impact of standards on AUREL’s internal processes

Quality testing is an integral part of the entire process, ensuring compliance with OEM standards and confirming long-term process stability. At AUREL, the following tests and controls are carried out, among others:

- Measurement of coating thickness: Precise measurements ensure that each layer has the required thickness across the entire surface. A layer that is too thin would not provide sufficient protection, while an excessively thick layer could complicate subsequent processing.

- Degreasing tests: Each component must be completely free of grease and contaminants. Bath concentration, temperature, and exposure time are carefully monitored to ensure a perfectly clean surface prepared for the next process steps.

- Measurement of the passivation layer: After passivation, the amount of elements such as titanium or silicon remaining on the surface is monitored. These elements contribute to enhanced corrosion resistance and good processability of the component.

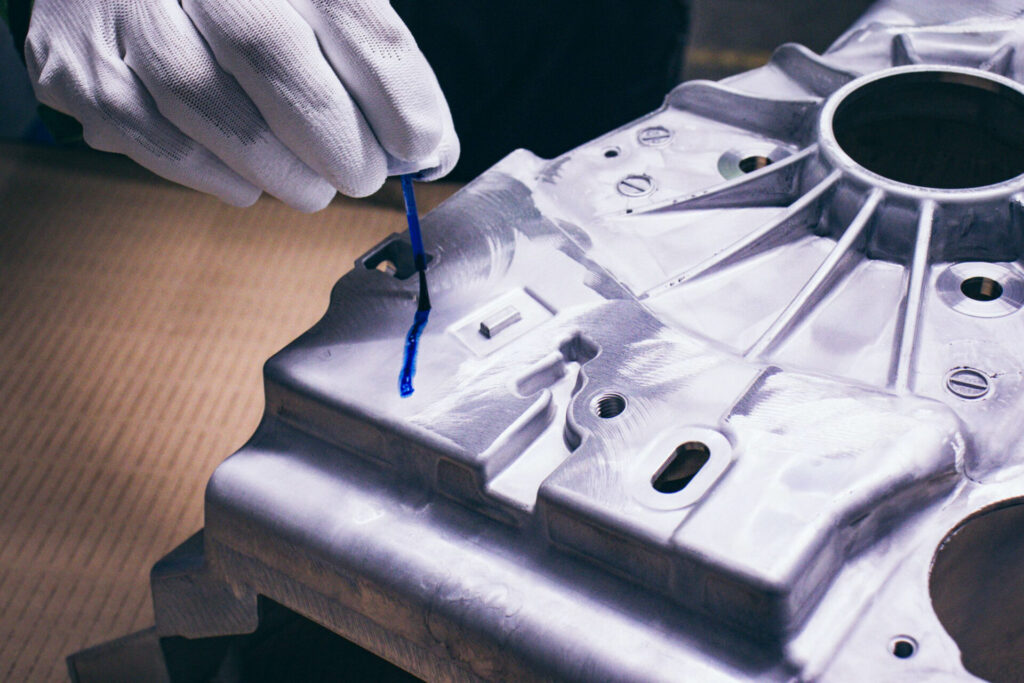

- Verification of correct riveting: Mechanical strength is verified using torque wrenches. Components must demonstrate that joints remain secure in aluminium parts without slipping or damage.

Monitoring of chemical baths in the AUREL laboratory: Stable bath quality is a fundamental prerequisite for process repeatability. In the AUREL laboratory, parameters such as protective layer thickness, surface tension, and titanium and silicon content are monitored daily using XRF analysis.

Manufacturer requirements are also reflected in the company’s internal organisation. Various types of audits are carried out regularly, including internal audits as well as audits conducted by customers and certification bodies. These primarily include system audits, process audits, and product audits. Employees prepare hundreds of documents each year, all of which undergo strict auditor review. Strong emphasis is also placed on regular employee training and environmental protection.

An individual approach within OEM standards

AUREL builds on an individual approach to each customer. The company is not limited to a specific type of component, material, or surface treatment method. It is able to adapt to partner requirements and apply processes precisely according to customer specifications. A typical example is the option for customers to introduce their own internal standards for surface treatment – standards that AUREL is fully capable of implementing in practice.

We are flexible and able to meet even highly specific requirements from renowned automotive manufacturers worldwide. We ensure the highest quality for your components as well – contact us.