Faster development, fewer prototypes, lower costs – this is what CAE analyses (Computer-Aided Engineering) enable automotive manufacturers to achieve today. Virtual modelling provides accurate simulations of vehicle and component behaviour even before production begins. It allows engineers to identify design weaknesses, optimise concepts, and significantly accelerate the entire development process. AUREL has more than 30 years of experience in CAE analyses and was among the pioneers of this discipline in the Czech Republic.

Virtual testing instead of physical prototypes

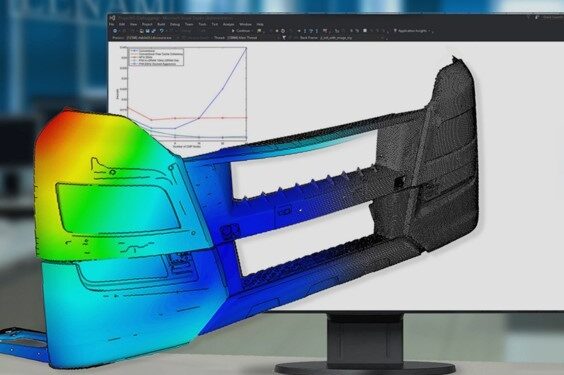

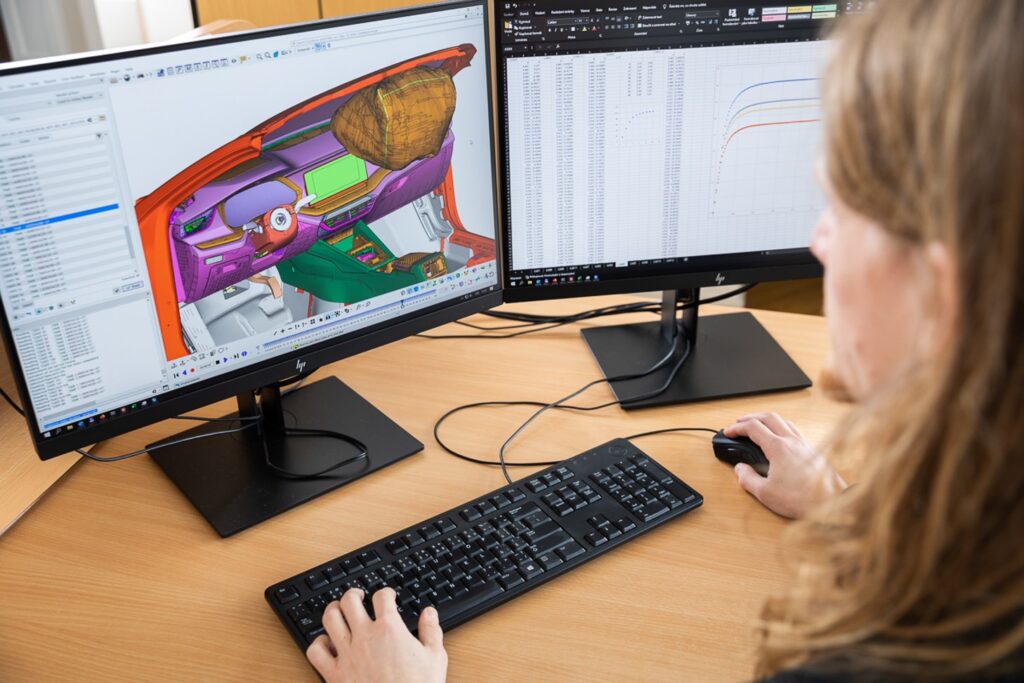

The foundation of CAE simulations is the creation of a virtual model based on the real geometry of a vehicle. Material properties are assigned to individual components and their behaviour is then simulated under various conditions – from normal operation to crash scenarios. Unlike physical testing, virtual simulations do not destroy any components. The model can be repeatedly examined in detail, disassembled, and modified as needed. Engineers and technicians gain in-depth insight into structural behaviour, including areas that cannot be instrumented during real tests.

Types of simulations

Thanks to powerful computational tools, it is possible to simulate the behaviour of individual components as well as entire systems under various operating conditions. Modern virtual modelling includes a wide range of simulation methods:

- Structural simulations (FEM) – show how structures behave under loads such as impacts, vibrations, or temperature changes. They help identify weak points, increase durability, and reduce development and testing costs.

- Multibody simulations (MBS) – model the dynamic behaviour of interconnected moving bodies. They are widely used for simulating engines, transmissions, vehicle chassis, as well as robotic arms or production lines.

- CFD simulations – provide detailed analysis of fluid flow and heat transfer. At AUREL, these calculations are used to solve complex tasks involving coupled flow, thermal effects, and mechanical loads. Typical applications include fluid flow in lubrication channels and piping systems, brake cooling in vehicles, or the design of turbomachinery such as wind turbines.

- Multiphysics simulations – combine multiple physical domains, including mechanics, heat transfer, fluid flow, electromagnetism, and control logic. They enable realistic modelling of systems where these phenomena interact with one another.

Speed, confidence, and efficiency in development

Thanks to virtual testing, engineers can identify problems before they occur. Weak points become visible early, designs can be optimised, and risks are minimised before production begins. Most issues are resolved prior to physical testing, which then serves primarily as validation. Using topological optimisation, for example, engineers can reduce component weight, improve stiffness, or distribute material more efficiently.

CAE analyses significantly accelerate development, reduce the number of physical prototypes, and deliver better results at lower cost. A key factor is the quality of material models – their measurement and calibration are among the main strengths of the AUREL team. With more than twenty CAE specialists, AUREL performs analyses for automotive manufacturers worldwide. “There is a simple rule: the quality of analysis results depends on the quality of your material models. This is exactly where we are strong – and why our customers keep coming back,” says Miloš Müller, Head of CAE Analyses.

The future of CAE: faster through machine learning and AI

Simulations increasingly leverage artificial intelligence, where machine learning and neural networks significantly speed up both computation and result evaluation. “Machine learning and artificial intelligence are developing at an unprecedented pace, bringing new possibilities to simulations. Those who fall behind will quickly lose competitiveness and may have little chance of success in this field within just a few years,” Müller warns.

The strength of 30 years of experience

Virtual modelling is a key tool for efficient, safe, and sustainable vehicle development. AUREL applies CAE simulations not only in the automotive industry, but also in other sectors – such as aerospace or thermal analyses for various industrial applications. Thanks to strong theoretical expertise, AUREL is able to solve non-standard customer challenges, where success often begins with correctly defining the problem itself. The team also tackles unconventional simulations for which no standard procedures exist – areas that many companies avoid. Moreover, they can explain complex results in clear, understandable terms. This is one of the reasons why AUREL is regarded as a key player in this field within the Czech Republic.

Looking for confidence in your development process? With virtual modelling by our experts, you can identify issues before they arise – and gain the competitive edge that truly matters.